September 11, 2017

Understanding Break-In Time: Introducing Nitro™ an Intrinsic Start-Up Aid

Is your press fabric break-in time costing you production? Do you wish that new felts performed more as they do once they are settled?

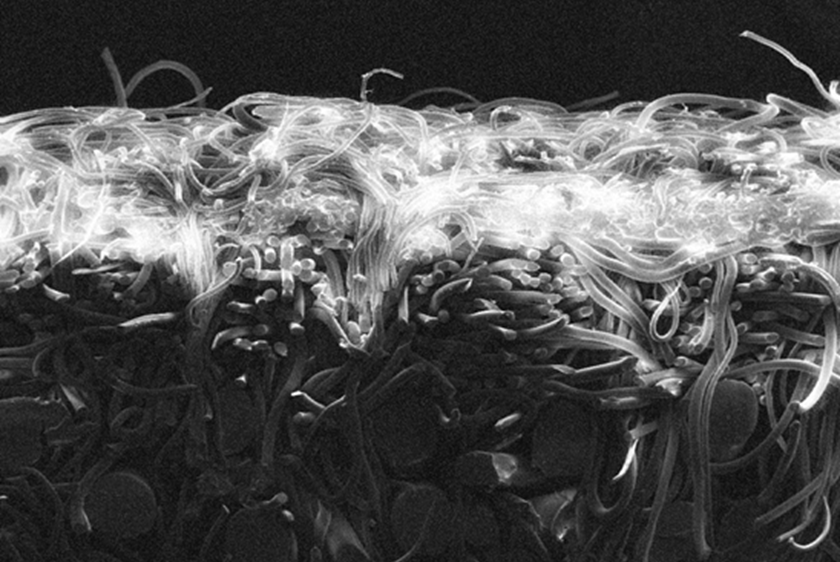

The reason press fabrics take time to settle into their running state is that the batt structure and base construction both need time to reach optimum density. The low initial density of new fabrics causes the uhle boxes to remove too much water from the felt loop, which in turn affects nip saturation and pressing efficiency. Press fabric designers have to consider this effect to ensure that most of the useful life of the felt falls within the optimum range.

Additional details on this cutting edge technology click here.

About AstenJohnson

AstenJohnson is a global manufacturer of pulp & paper machine clothing, advanced and filtration fabrics, filaments, and nonwoven fabrics for filtration, automotive, cured-in-place piping and composites. The company has manufacturing facilities in Europe, Asia and North America, with corporate headquarters in Charleston, South Carolina. AstenJohnson emphasizes quality in its innovative products and builds long-term relationships with its customers, associates, suppliers and communities based on five values: Safety, Excellence, Integrity, People, and Sustainability. Together, these values contribute to customer satisfaction.

Contact