“Percentages are for accountants”

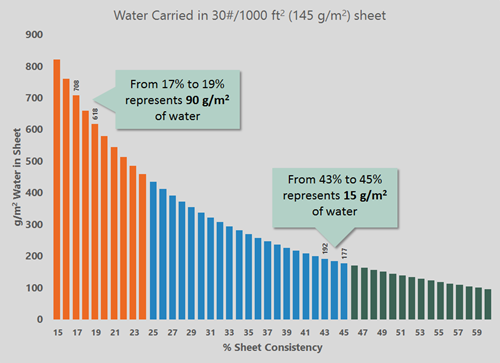

Not that there’s anything wrong with that. If you’re a technical person, you have to watch out for what is hidden behind those pesky ratios. A great example in papermaking is the classic “just a couple points of sheet solids.” It’s important to remember that a couple points off the couch is very different than a couple points after the press. The graph below illustrates what those 2 points of consistency mean at 2 different points along the machine.

So what, you say? So…

1) A 2 point consistency drop at the couch could mean 25% more water has to be removed in the press to maintain solids out of the press.

2) Slight variations off the couch have a significant impact on pressing efficiency.

3) Off-couch consistency is a critical process control variable.

4) The difference between a press operating efficiently and causing you a lot of grief is a very, very small amount of water.